WHAT IS E-BEAM EVAPORATION

E-beam evaporation is a process similar to thermal evaporation i.e. a source material is heated above its boiling/sublimation temperature and evaporated to form a film on the surfaces that is stroke by the evaporated atoms. This evaporation method has just like thermal evaporation a pore ability to cover steps which also makes this method ideal for lift-off processes. A noticeable advantage of e-beam evaporation over thermal evaporation is the possibility to add a larger amount of energy into the source material. This yields a higher density film with an increased adhesion to the substrate. Because the electron beam only heats the source material and not the entire crucible, a lower degree of contamination from the crucible will be present than in the case of thermal evaporation. By using a multiple crucible E-beam gun, several different materials can be deposited without breaking the vacuum.

Products

Electron beam deposition system

The Cryofox electron beam deposition system is a series of vacuum deposition systems that use electron beam deposition. You can get an electron beam deposition system that has either a single or a split chamber. Either form of electron beam deposition system is usable for both small-scale manufacturing of high-end components and for R&D projects. The electron beam deposition system can contain up to eight different materials in its sources making it possible to perform advanced multi-layer structures and still maintain the vacuum.

Polyteknik provides the following electron beam deposition systems:

1. The Discovery 502 electron beam deposition system

Simple deposition system for advanced research

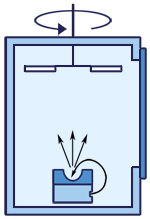

2. The Explorer 600 electron beam deposition system

Ultra clean processes with a minimum of efforts

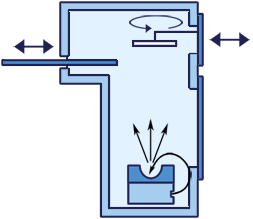

3. The Explorer 700 electron beam deposition systemm

Alloy layers from pure materials by co e-beam deposition

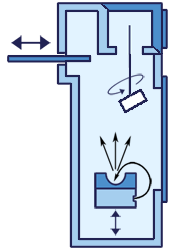

4. The Explorer 500 Glad electron beam deposition system

Manufacture controlled nanostructures by glancing angle deposition